- Rectifier

- Power Supply

- Test Device

- Excitation Device

- Rectifier Power Supply Device

- Mine Traction Substation Rectifier Complete System

- High Frequency Inverter Switch Charging Rectifier Power Supply Device

- High Frequency Inverter Switch Quick Charging Rectifier Power Supply Device

- Automation Integrated Control System

- Computer Control DC Traction Motor Feedback Test Bench

- Intelligent Maintenance-free DC Power Supply Panel

- Plasma Combustion System

GQF-6DD (12DD) Series Mine Traction Substation Rectifier Complete System

Product Introduction:

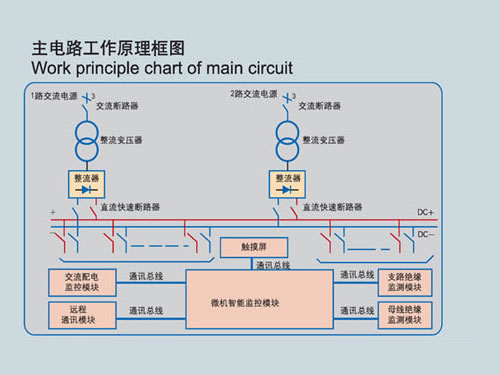

Mine traction substation rectifier complete system is a kind of DC traction power supply complete system. This rectifier power supply device adopts low voltage or high voltage silicon rectifier transformer for isolation decompression, three-phase bridge silicon rectifier to get the necessary DC traction power supply. Two circuit AC switch cabinet gives power distribution to each DC traction power supply system. This DC traction power supply complete system (rectifier power supply device ) consists of traction transformer, traction silicon rectifier, DC electrical switch cabinet, DC feeder switch cabinet, DC bus grounding insulation monitoring, branch current detection and PLC microcomputer monitor system. When multiple sets of rectifiers operate in parallel connection, we can constitute respectively 12-pulse, 18-pulse and 24-pulse rectifiers through changing rectifier transformer's coupling grouping. Thus DC traction power supply complete system can greatly reduce 3, 5, 7, 11 harmonic generated by rectifier transformer to network side, improve the quality of electricity and protect the safety of other equipments. The technical design of this rectifier power supply device conforms to the technical design standard of traction DC substation silicon rectifier device of iron ore, copper and tin ore. This DC traction power supply complete system can also fully meet the needs of mine traction underground DC substation system.

Main Technical Features:

1. Mine traction substation rectifier complete system can carry out long-term continuous full load work, 150% overload two hours, 200% 30mins and 300% one min.

2. This rectifier power supply device has many protection functions including protections of over temperature of rectifier transformer, quick fuse, over temperature of silicon rectifier components, overheated alarm of wind machine and output DC breaker.

3. According to system's requirement, we can configure this DC traction power supply complete system with PCL computer monitor system, DC bus bar grounding insulation detection protection, feedback loop branch current detection and alarm protection system.

4. Ground PLC touch screen operation system of this rectifier power supply device can be configured to display, store and record working current, voltage of silicon rectifier and real-time curves of feedback loop branch current.

5. We can provide CAN BUS, PROFIBUS, ETHERNET, RS485 and RS232 fiber communication to realize remote control or monitor.

Main Specifications of This DC Traction Power Supply Complete System:

| Power Supply | DC275V, 600V, 1000V, etc |

| Rated Output Voltage | 6V, 12V, 15V, 18V, 24V, 36V, any voltage specification |

| Rated Output Current | DC400A, 600A, 1000A, 1500A, 2000A, 3000A, 4000A, 5000A, etc |

| Rectifier Transformer Short Circuit Impedance Percentage | ≤4% |

| Rectifier Efficiency | ≥98% |

| Operation Mode | local or remote operation mode |

| Rectifier Mode | 6-pulse silicon rectifier or 12-pulse silicon rectifier |

| Rectifier Transformer | epoxy resin casting dry type |

TallKee rectifier is a professional manufacturer and supplier of mine traction substation rectifier complete system in China. In addition to this DC traction power supply complete system, we also produce high frequency inverter switch charging rectifier power supply device and high frequency inverter switch quick charging rectifier power source device. Our products have been exported to USA, Germany, Australia, Singapore, India, Brazil, Iran, Vietnam, Kazakhstan and Malaysia, etc.

- High Frequency Inverter Switch Charging Rectifier Power Supply Device

The high frequency inverter switch charging rectifier power supply device adopts IGBT inverter soft switch AC-DC/DC-AC/AC-DC rectifier, LC filtering ...

The high frequency inverter switch charging rectifier power supply device adopts IGBT inverter soft switch AC-DC/DC-AC/AC-DC rectifier, LC filtering ...

- High Frequency Inverter Switch Quick Charging Rectifier Power Supply Device

High frequency inverter switch quick charging rectifier power supply device adopts IGBT inverter soft switch AC-DC/DC-AC/AC-DC rectifier and LC filtering...

High frequency inverter switch quick charging rectifier power supply device adopts IGBT inverter soft switch AC-DC/DC-AC/AC-DC rectifier and LC filtering...