High Frequency Plating Rectifier,Inverter Soft Switch Electroplating Rectifier

- Rectifier

- Electrolytic Rectifier

- KGHS Series Electrolytic Cleaning Rectifier Device

- SCR Electrolytic Rectifier

- KGHS-6DD (12DD)-PLC KGHS-6DD (12DD)-PLC Series SCR Electrolytic Rectifier

- Inverter Soft Switch Electrolytic Rectifier

- Electroplating Rectifier

- Silicon Controlled Electroplating Rectifier

- KGDF/KGDF(S)/KGSF21-150A-230V Silicon Controlled Electroplating Rectifier

- Silicon Controlled Reversing Electroplating Rectifier

- Inverter Soft Switch Electroplating Rectifier

- Thyristor Rectifier

- Thyristor Electrolytic Rectifier

- Thyristor Electroplating Rectifier

- SCR Reversing Rectifier

- High Frequency Rectifier

- High Frequency Electrolytic Rectifier

- WHFB Series High Frequency Electrolytic Rectifier

- High Frequency Electroplating Rectifier

- Power Supply

- Test Device

- Excitation Device

- Rectifier Power Supply Device

- Automation Integrated Control System

- Computer Control DC Traction Motor Feedback Test Bench

- Intelligent Maintenance-free DC Power Supply Panel

- Plasma Combustion System

WHFD-Series Inverter Soft Switch Electroplating Rectifier

- WHFD 1000A 24V High Frequency Inverter Soft Switch Reversing Rectifier Power Supply

WHFD 1000A 24V high frequency rectifier power supply is a kind of soft switching power supply adopting IGBT soft switch rectifier technology. It is mainly used as ...

WHFD 1000A 24V high frequency rectifier power supply is a kind of soft switching power supply adopting IGBT soft switch rectifier technology. It is mainly used as ...

Description:

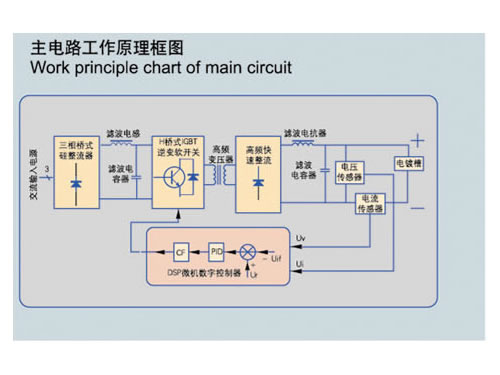

The inverter soft switch electroplating rectifier adopts IGBT high frequency inverter soft switch rectifier technology. This high frequency plating rectifier is mainly used as all kinds of metal and nonmetal surface electroplating rectifier power supplies (like electroplating zinc, nickel, chrome and titanium, etc). The inverter soft switch electroplating rectifier can also be used as electrolytic rectifier power supply, common anodizing power supply and DC heating power supply, and so on. This high frequency plating rectifier has a special structure using water cooling method. It has obvious energy saving effect. The inverter soft switch electroplating rectifier can provide stable current and voltage, and has soft starting and multiple protection functions. The plated layer has excellent compactness, excellent wear resistance and high rigidity. This high frequency plating rectifier shows excellent process versatility in electroplating production. We use export wooden case to pack inverter soft switch electroplating rectifiers after fumigation treatment. With waterproof, anti collision and good fixation, package will be strong and durable during transportation to stop damage.

Main Parameters of This High Frequency Plating Rectifier:

| Power Supply | 3P AC380V, 400V, 450V, etc. frequency (50Hz) |

| Rated DC Output Voltage | 6V, 12V, 15V, 18V, 24V, 36V, any other voltage specification |

| Rated DC Output Current | 500A, 1000A, 1500A, 2000A, 3000A, 4000A, 5000A, 6000A, 8000A, 12000A, 15000A, 18000A, 20000A, any current specification |

| Soft Start Working Time | 0-200s |

| Constant Current Control Accuracy | ≤±1% |

| Constant Voltage Control Accuracy | ≤±1% |

| IGBT Inverter Switch Frequency | 20KHZ-25KHZ |

| Rectifier Efficiency | ≥92% |

| Output Current Ripple Coefficient | ≤1-3% |

| Pulse Phase-Shifting Resolution | ≤1μs |

Main Technical Features of High Frequency Plating Rectifier:

1. The inverter soft switch electroplating rectifier is of super small volume and light weight. The volume is 1/5 to 1/8 of SCR, while the weight is 1/20 to 1/40.

2. According to customers' requirements, we can provide CAN BUS, PROFIBUS, ETHERNET, RS485 and RS232 fiber communication to realize remote control or monitor high frequency plating rectifiers.

3. Rectifier transformer's iron core adopts high-quality superfine microcrystalline materials, with no-load loss less than 2% and 4% to 5% energy-saving compared to common switch rectifier transformers.

4. The inverter soft switch electroplating rectifier adopts IGBT inverter soft switch rectifier, saving 5% electricity than common switch rectifier power supplies, 15-25% than SCR.

5. This high frequency plating rectifier provides local and remote operation modes.

6. The master controller adopts DSP microcomputer digital PWM control.

7. Delivery time will be 2-8 weeks decided by your technical data.

8. The inverter soft switch electroplating rectifier has several protection functions, such as openphase, overvoltage, under voltage, quick fuse or fuse alarm protections of AC power supply, and output over current and current limiting protections. This high frequency plating rectifier also possesses functions of output short circuit and instantaneous overload protections, IGBT RFSM, quick rectifier diode components, switch rectifier transformer and bus copper bar overheat, fan overheating or excess water pressure and low block trigger pulse protections.

TallKee rectifier is a professional manufacturer and supplier of high frequency inverter soft switch electroplating rectifiers in China. In addition to this high frequency plating rectifier, we also produce silicon controlled and silicon controlled reversing electroplating rectifiers. Our products have been exported to USA, Germany, Australia, Singapore, India, Brazil, Iran, Vietnam, Kazakhstan and Malaysia, etc.

- Silicon Controlled Electroplating Rectifier

This SCR rectifier adopts 6 pulse or 12 pulse SCR rectifier. The KGDF series electroplating rectifier is mainly used as all kinds of metal and ...

This SCR rectifier adopts 6 pulse or 12 pulse SCR rectifier. The KGDF series electroplating rectifier is mainly used as all kinds of metal and ...

- Silicon Controlled Reversing Electroplating Rectifier

This SCR rectifier adopts 6-pulse or 12-pulse SCR automatic reversing rectifier. KGDF series reversing rectifiers are mainly used as all kinds of metal and ...

This SCR rectifier adopts 6-pulse or 12-pulse SCR automatic reversing rectifier. KGDF series reversing rectifiers are mainly used as all kinds of metal and ...