- Rectifier

- Power Supply

- Anodizing Power Supply

- SMDF-JDY PLC Control Anodizing Power Supply

- SMDF-MDY-PLC DC Superimposed Pulse Anodizing Power Supply

- High Frequency Inverter Soft Switch Anodizing Power Supply

- Thyristor Rectifier Anodizing Power Supply

- DC Superimposed Pulse Anodizing Power Supply

- Asymmetric AC Pulse Anodizing Power Supply

- Titanium Alloy Pulse Anodizing Power Supply

- Electroplating Power Supply

- Silicon Controlled Rectifier Electroplating Power Supply

- KGBF-6000A18V Silicon Controlled Electrolytic Rectification Power Supply

- SCR Reverse Electroplating Power Supply

- Inverter Soft Switch Electroplating Power Supply

- Pulse Electroplating Power Supply

- SCR Power Supply

- SCR Anodizing Power Supply

- SCR Rectifier Anodizing Power Supply

- Thyristor Electroplating Power Supply

- Silicon Controlled Reversing Electroplating Power Supply

- Switching Power Supply

- Soft Switching Electroplating Power Supply

- Soft Switching Anodizing Power Supply

- Heating Power Supply

- Czochralski Furnace Heating Power Supply

- Sapphire CZ Furnace Heating Power Supply

- KGPS-Series Medium Frequency Induction Heating Power Supply

- IGPS-Series Medium Frequency Induction Heating Power Supply

- Engine Starting Power Supply

- Aircraft Engine Starting Power Supply

- Tank Engine Starting Power Supply

- Armored Vehicle Engine Starting Power Supply

- Micro Arc Oxidation Power Supply

- Medium Frequency Static Variable Frequency Power Supply

- High-precision Enabling Power Supply

- WHSB-GJD Series High Frequency Switch Electrolytic Rectifier Power Supply

- Digital Control High Voltage DC Pulse Power Supply

- Test Device

- Excitation Device

- Rectifier Power Supply Device

- Automation Integrated Control System

- Computer Control DC Traction Motor Feedback Test Bench

- Intelligent Maintenance-free DC Power Supply Panel

- Plasma Combustion System

KGBF-6000A18V Silicon Controlled Electrolytic Rectification Power Supply

Features

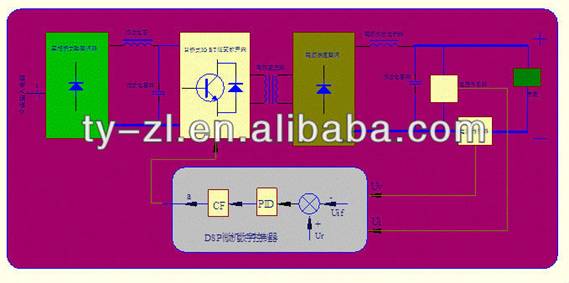

1. KGBF-6000A18V silicon controlled electrolysis power supply adopts DSP for digital control.

2. Double channels are available for hot spare, which makes this SCR power supply switch without stop and disturbing.

3. It adopts SCR 6-pulse rectification mode. There are 6KV, 10KV, 20KV and 35KV incoming lines for voltage regulation.

4. The rectifier transformer of this electrolysis power supply can carry out 9 to 27 grade on-load voltage regulation (coarse adjustment) and secondary side SCR regulates phase shifting voltage (accurate adjustment).

5. Local control and remote control can be converted mutually. This SCR power supply can choose constant current or constant voltage operation mode.

6. KGBF-6000A18V silicon controlled electrolysis power supply use CAN BUS, PROFIBUS, INDUSTRY ETHERNET, RS485 and RS232 optical fiber for communication.

Application

This electrolytic SCR power supply is suitable for nonferrous metal electrolysis refining (copper, zinc, nickel, lithium, lead, etc.), copper electrolysis, aluminum electrolysis, rare earth electrolysis, salt water electrolysis, chemical electrolysis, etc. KGBF silicon controlled electrolysis power supply can also be used for electrolytic polishing, electrolytic brightening, electrochemical polishing, electrolytic oxidation, plasma electrolytic oxidation, electrolytic iron, electrodeposited copper foil, electrolytic foil, electrolytic copper foil, etc.

Technical Parameters

| Name | KGBF-6000A18V Electrolytic SCR Power Supply |

| Input Power | AC380V/415V/460V 3 Phase |

| Output Current | 10000A (0-10000A continuously adjustable) |

| Output Voltage | DC 4V (0-4V continuously adjustable) |

| Rated Output Power | 40 kW |

| Control Mode | Constant current mode or constant voltage mode can be selected. |

| Power Factory | 0.85 |

| Ripple | less than 5% at rated voltage |

| Constant Current Control Accuracy | ≤ ± 1% |

| Protection Grade | No less than IP54 |

| Protection Function | -Over/Low Voltage Protection -Over/Low Current Protection -Short Circuit Protection -Over Temperature Protection -Lack Water Protection |

Drawing of KGBF Silicon Controlled Electrolysis Power Supply

1. DC output automatic steady current accuracy is ≤ ±1%.

2. Trigger pulse asymmetry of this SCR power supply is ≤ 0.1°.

3. Pulse phase-shifting resolution is ≤1µs.

4. Rectifier transformer and thyristor rectifier in main circuit adopts cophase counter parallel connection technology, which greatly reduces eddy current loss of accessories.

5. With PLC colorful touch screen, the operation interface is flexible and has a good vision. It can timely record all kinds of parameters and historical curves of SCR electrolysis power supply’s operation.

TallKee rectifier has a long history of over 50 years in R&D and manufacturing electrolytic SCR power supply in China. In addition to SCR electrolysis power supply, we also produce pulse silicon controlled reversing electroplating power supply, inverter soft switch and pulse electroplating power supplies. Our products have been exported to USA, Germany, Australia, Singapore, India, Brazil, Iran, Vietnam, Kazakhstan, etc.

- KGDF(S)--6DD(12DD)KGDF-6DD(I12DD) Series Silicon Controlled Rectifier Electroplating Power Supply

Silicon controlled rectifier electroplating power supply is a kind of electroplating power supply that can convert power frequency AC ...

Silicon controlled rectifier electroplating power supply is a kind of electroplating power supply that can convert power frequency AC ...

- KGDF(S)-6ZH(12ZH) Series SCR Reverse Electroplating Power Supply

SCR reverse electroplating power supply is a device in accordance with the requirements of the electroplating process. This type of ...

SCR reverse electroplating power supply is a device in accordance with the requirements of the electroplating process. This type of ...